To maintain smooth operations, meet customer demands, and stay competitive, it’s imperative that we do what it takes to maximize manufacturing efficiency. However, bottlenecks are an inherent part of any precision machine shop, and managing them is key to optimizing productivity.

At Reata, we don’t allow bottlenecks to be an excuse that we try to overcome. Our team acknowledges bottlenecks, faces them head-on, and addresses them proactively so they don’t disrupt our operations—or our customers’ supply chains.

The Nature of Bottlenecks in Precision Machine Shops

In a steady manufacturing environment in which a team makes the same handful of parts over and over, the bottlenecks typically occur in one place; this means that with efforts to improve that process, a bottleneck can disappear, at least for a period of time. This is not the case in a contract manufacturing setting that demands constant change.

In a job shop like ours, where product mix constantly changes, bottlenecks are continuously shifting depending on factors like workload, staffing, equipment maintenance, and material availability. As a result, our team must be agile, going out of our way to identify and mitigate bottlenecks to stop them in their tracks before they can disrupt our momentum.

Reata’s Agile Approach to Addressing Bottlenecks

Our team achieves manufacturing efficiency by proactively handling potential bottlenecks in the following ways:

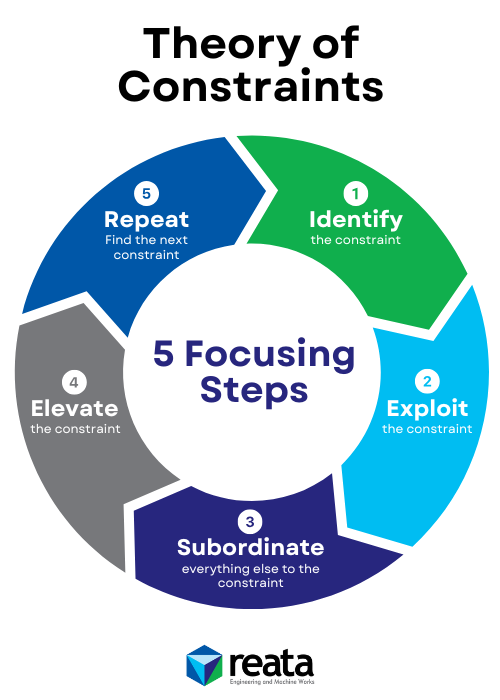

Using Lean Manufacturing and Theory of Constraints

At Reata, we utilize Lean manufacturing principles and the Theory of Constraints (ToC) to effectively manage bottlenecks. ToC emphasizes identifying the primary constraint in the system and ensuring that all other processes support and optimize that constraint. Some key steps we follow include:

- Identifying constraints: We conduct regular evaluations of our processes to determine where bottlenecks exist, whether in our engineering stages, precision machining services, or quality assurance processes.

- Optimizing workflow around the constraint: Once a bottleneck is identified, we adjust operations around it to maximize manufacturing efficiency.

- Ensuring stability before standardization: Before implementing new standards, we establish process stability by eliminating non-value-added tasks.

- Continuous improvement through PDSA cycles: Using Plan-Do-Study-Adjust (PDSA) cycles, our team tests improvements in real-time, analyzes results, and refines processes to reduce bottlenecks.

Improving Process Flow in Our Engineering and Manufacturing Services

We’ve significantly expanded our engineering team to identify and resolve bottlenecks efficiently. By leveraging intentional DfM principles, we analyze production methods early in the design phase to prevent bottlenecks before they occur.

Additionally, Reata conducts complex testing procedures in-house to improve our production flow.

Balancing Product Mix to Optimize Quality and Throughput

Bottlenecks sometimes occur in our quality department due to an influx of prototype projects that require extensive quality checks. To address this, we carefully manage product mix by balancing high-complexity jobs with quick-turnaround projects, ensuring efficiency without overloading a single department.

Leveraging Advanced Machining Capabilities

Investing in cutting-edge technology is another way we enhance manufacturing efficiency here at Reata. Our complex CNC machining capabilities allow us to reduce setup times and process intricate, tight-tolerance parts with fewer operations. This approach supports single-part flow, a key Lean manufacturing principle that minimizes work-in-progress inventory and accelerates turnaround time.

Managing External Constraints

Bottlenecks aren’t just internal. In contract manufacturing, external vendors can also create delays. To mitigate this, we adopt single-part flow practices and stagger deliveries to external partners to prevent large batches from becoming constraints within our facilities.

How Customers Benefit from Reata’s Efficiency-Driven Approach

Transparency and Open Communication

At Reata, we maintain an open line of communication with customers, providing clear and realistic delivery dates based on our actual capacity and workflow. This level of honesty is critical for industries like aerospace machining and medical machining, where missed deadlines can lead to significant financial consequences.

Seamless Processes, No Matter What

Effective precision machine shops should manage bottlenecks without letting customers feel any impact.

Picture a duck floating on water. Above the surface, the duck looks smooth, relaxed, and comfortable. Meanwhile, the duck’s feet constantly kick and move to stay afloat. This is reminiscent of how we operate here at Reata; our customers see a calm, cool, and collected manufacturing partner; meanwhile, we’re constantly working behind the scenes to ensure smooth, efficient, and on-time deliveries—diligently kicking our feet unbeknownst to our customers.

Bottlenecks are inevitable in manufacturing, but they don’t have to be obstacles. Reata continuously optimizes manufacturing efficiency through a combination of Lean and ToC principles, strategic resource allocation, and cutting-edge capabilities. By proactively identifying constraints and implementing innovative solutions, we ensure that our customers receive high-quality parts on time—every time.

Request a quote to partner with Reata’s proactive team.