Manufacturing Engineers Are Problem Solvers—and Contract Manufacturing Is Full of Problems

Across industries and innovations, engineers are the silent problem-solvers behind the scenes. Most of the technologies and infrastructure we rely on daily – from the roads we travel on to the devices we access information on – exist because of engineers. And in precision machining, talented manufacturing engineers aren’t just helpful, they’re essential. Yet many […]

The Global Web of American Manufacturing: Why International Connections Matter

In this country, manufacturing isn’t fading—it’s evolving. U.S. machine shops like Reata are thriving in a global environment where international collaboration, advanced automation, and customer relationships drive innovation and growth. As a precision machining business that ships to countries across various hemispheres, we understand firsthand how American manufacturing is deeply connected to a worldwide network […]

The True Test of a Precision Machine Shop? How We Respond to Mistakes

A precision machine shop typically operates like many others when things are running smoothly. If everything is on time, parts meet specifications, and processes flow seamlessly, customers may not notice much difference between one shop and another. But the true test of a shop’s value is revealed when something goes awry. At Reata, we believe […]

Why “Approximately Correct” Is Better Than “Perfectly Wrong” in Contract Manufacturing

Here at Reata, we’re fortunate to have a team of contract manufacturing professionals who take immense pride in what they do. And while having such fantastic people on board is the opposite of an issue, a few team members have had to work through a familiar challenge: over-perfection. Wait—over-perfection? That doesn’t sound like a problem, […]

Why Your Contract Manufacturing Partner Should Handle Production AND Inspection

In contract manufacturing, producing high-quality parts is only half the battle. The real challenge often lies in measuring components with unmatched precision. Many companies, including some of our customers, manufacture their parts in-house but send them to us for final inspection. The reason? Their own quality departments are prone to bottlenecks, slowing down production. At […]

Identifying and Overcoming Bottlenecks to Maximize Manufacturing Efficiency

To maintain smooth operations, meet customer demands, and stay competitive, it’s imperative that we do what it takes to maximize manufacturing efficiency. However, bottlenecks are an inherent part of any precision machine shop, and managing them is key to optimizing productivity. At Reata, we don’t allow bottlenecks to be an excuse that we try to […]

“Do Or Do Not; There Is No Try.” Wise Words from Yoda, the Mascot of Our Precision Machine Shop

One of the most common expressions here at Reata comes from a famous philosopher. No, this quote doesn’t come from the likes of Aristotle, Plato, Locke, Nietzsche, or Voltaire. It comes from a modern philosopher—a Jedi Master, to be specific: Yoda. “Do or do not; there is no try.” -Yoda It’s a simple yet powerful […]

What Should You Look for in a Manufacturing Partner? A Can-Do Attitude!

When it comes to selecting the right manufacturing partner, you might look into their technical capabilities, certifications, and equipment. These are all important factors that should certainly go into your decision, but there’s another critical element that often goes overlooked: attitude. At Reata, our “can-do” mindset has become a core part of our identity, driving […]

Better People, Better Parts: How Reata’s Talented Team Drives Our Customers’ Success

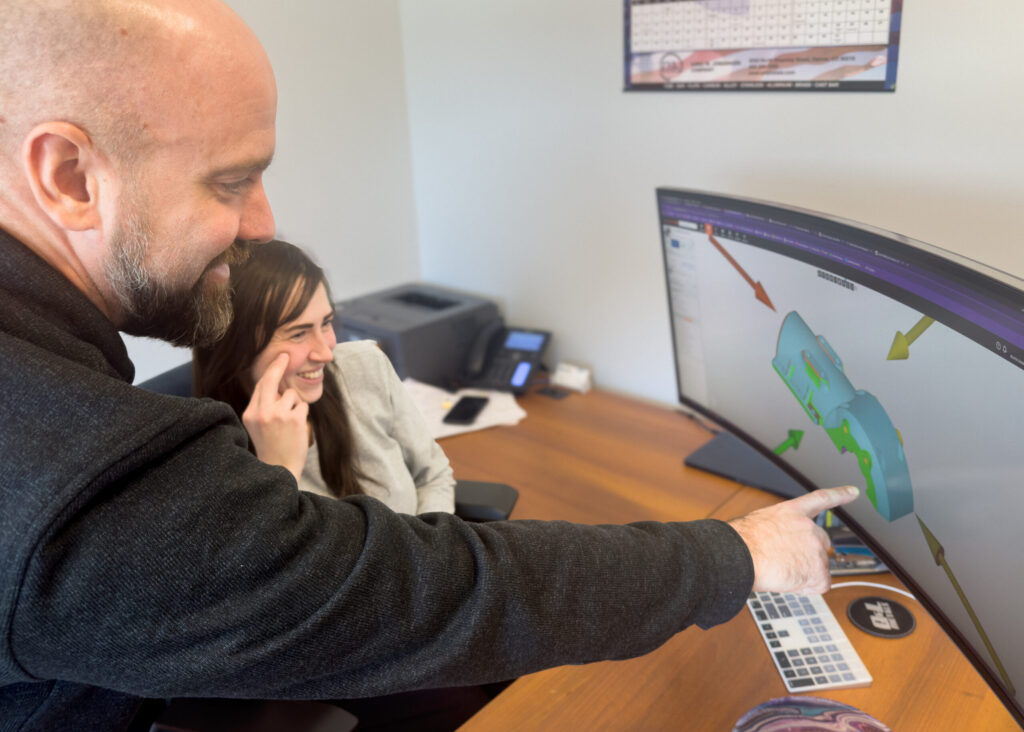

If you’ve partnered with the talented team at Reata before, you may be aware of the state-of-the-art software and equipment we use on a daily basis. From advanced automation systems to cutting-edge machining tools, we’ve made significant investments in the technology that powers our operations at our Colorado machine shop. But as advanced as our […]

Engineering Expertise at Reata: Supporting Complex Designs for Superior Results

Ready to get started? Discuss your project with our team! At Reata, we’re continuously advancing our capabilities, leveraging automation to meet the growing complexity of customer designs. But while automation significantly improves our efficiency and output, the backbone of this progress is our talented and highly technical engineering team. From designing intricate fixtures to developing […]