DFM Tip: Why You Should Model to the Mean, Not the Nominal

When producing high volumes of the same part, slight variations are inevitable. Tolerancing is just one way we account for these variations. However, a common misconception is that tolerances play the same role in prints and models. On prints, tolerances indicate the measurements for your ideal part, indicating how much deviation is acceptable. But when […]

Our Software Increases Visibility for Contract Manufacturing Customers

Reata Engineering constantly looks for ways to improve customer experiences, from the precision machining processes we develop to the software we use. We invest in state-of-the-art software to inform customers about the statuses of their contract manufacturing orders. We’re excited to announce that we’re preparing to roll out a new dashboard for increased customer visibility […]

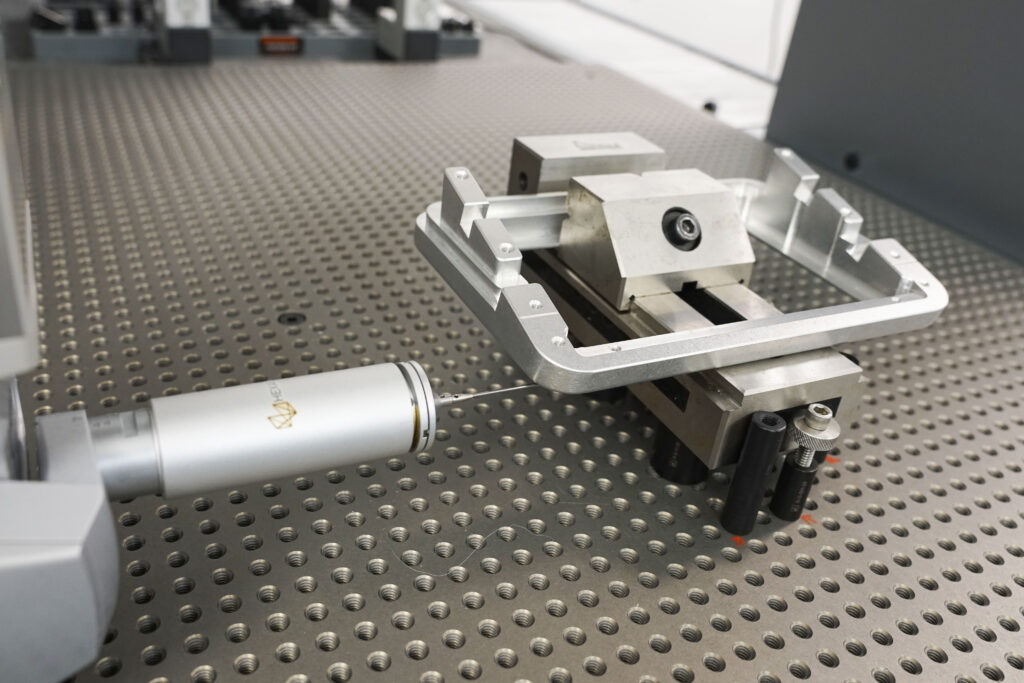

Why We Use Pre-Processed Parts for Complex CNC Machining Jobs

Let’s face it: customers don’t partner with Reata Engineering for our exceptional rectangular cut-outs. Customers choose Reata because we specialize in complex CNC machining jobs that make other precision machine shops sweat. So we don’t want to make them pay premium prices for simple services. That’s why, in many cases, we order pre-processed parts from […]

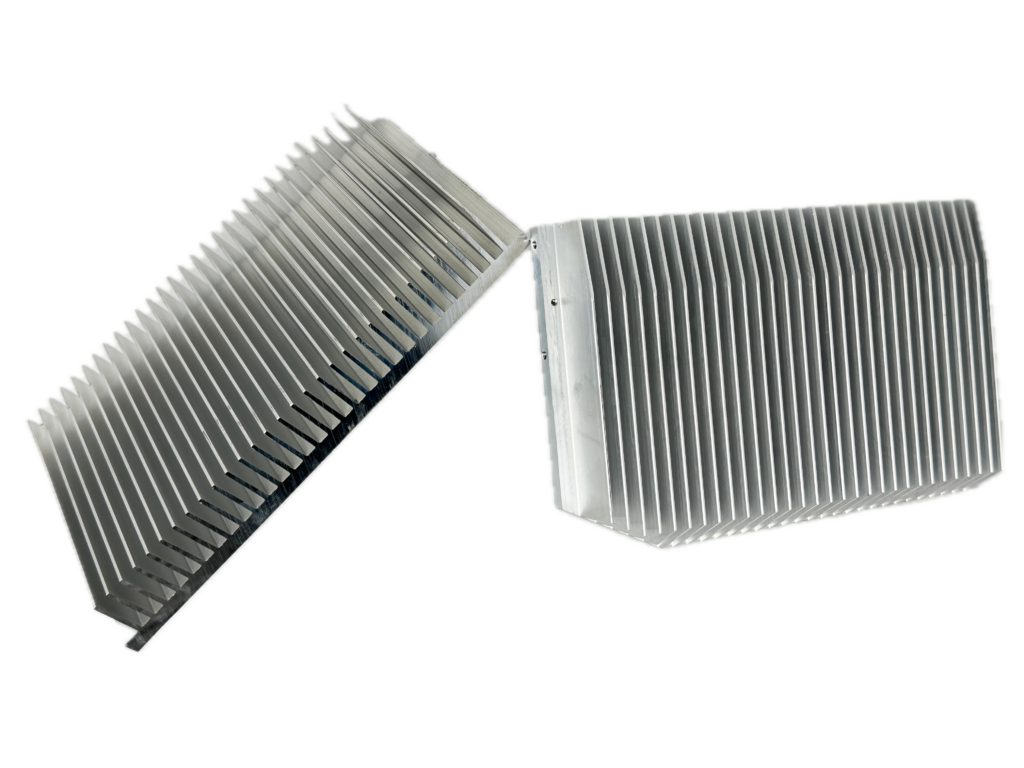

Reduce Contract Manufacturing Costs with Extrusion

Extrusion is an additive manufacturing process that involves heating a material and pulling it through a die to create a continuous length with the desired cross-section. The technique is similar to pushing Play-Doh through a mold. The formed length can then be sawed into sections. Additional machining operations may be necessary to add holes or […]

The Future of Contract Manufacturing Requires Your Participation

At Reata Engineering, we’re always looking forward. There’s no such thing as “good enough” at our Colorado machine shop—as soon as we get comfortable, we ask ourselves what we can do next. This mentality is central to everything we do, from maintaining a summer internship program to giving shop tours to competing precision machine shops […]

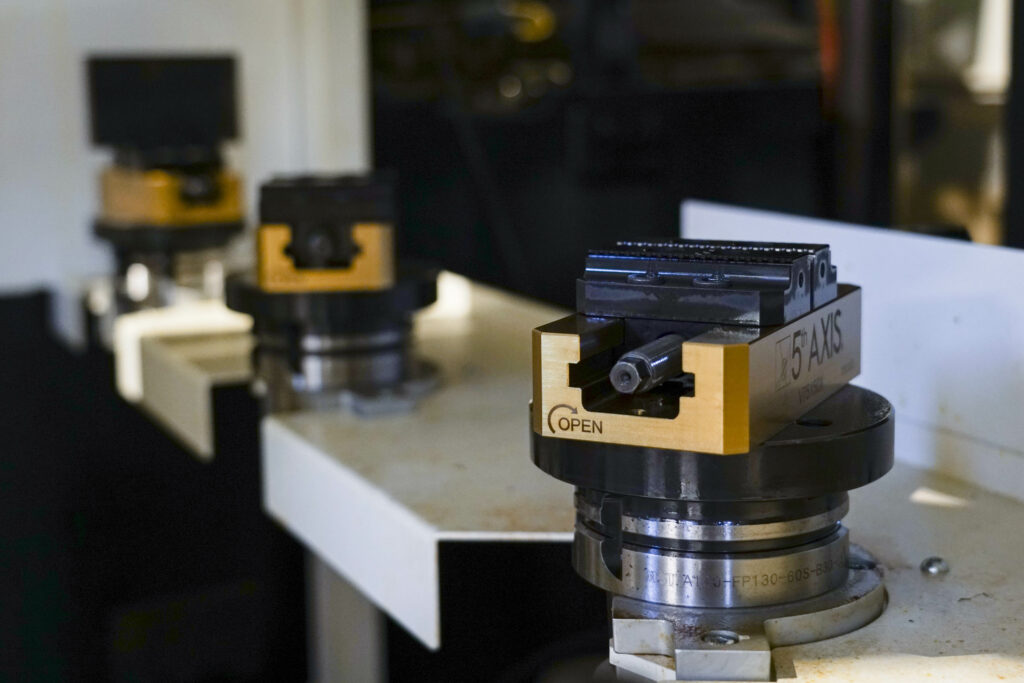

How 5-Axis Machining Accelerates the Prototyping Process

The manufacturing industry is entering the next generation of technology. Automation capabilities such as 5-axis machining and lights-out manufacturing are revolutionizing the way precision machine shops handle large part orders. As always, Reata is one step ahead. At our Colorado machine shop, we’re leveraging our robust 5-axis technology to improve our prototype machining services. Keep […]

5 Ways Reata’s Kanban Approach to Assembly Benefits Customers

At the heart of Reata Engineering’s assembly strategy is the kanban system. Kanban is an inventory system developed by Taiichi Ohno, the father of the Toyota production system. Successful application of kanban involves maintaining a stock of required parts for customers instead of waiting for an order to come through each time. At Reata, we […]

Use DFM Principles for Superior Prototype Machining Services

When beginning the prototyping process, many customers underestimate the importance of choosing an experienced contract manufacturing partner. However, by actively collaborating with a knowledgeable shop from the start, customers can expedite product development, optimize costs, and ensure a smoother transition into production. And don’t worry—It’s not too good to be true. It simply involves leveraging […]

DFM 101: 3 Reasons Reata Is a Superior DFM Partner

We believe in staying ahead of the curve because when we’re ahead, so are our customers. As a new generation of engineers enters the contract manufacturing industry in a period of rapid inflation, engineers and customers alike are seeking ways to decrease costs and simplify parts. Instead of sticking to tradition, we spent years perfecting […]

DFM 101: Getting Started with Design For Manufacturability

In precision machining, there is often a gap between design and manufacturing. What looks good on paper doesn’t always translate easily to the shop floor. In these cases, customers often spend valuable time and money on revisions and extensive back-and-forth communication with their manufacturing partner. DFM, or Design for Manufacturability, bridges the gap between what’s […]