Sustainability in Action at Our Colorado Machine Shop

As a precision machine shop that truly cares about the future we’re leaving behind for generations to come, Reata has made sustainability one of our core values. Sustainability influences how we purchase equipment, incorporate software into our operations, manage scrap material, and package and receive parts. From investing in energy-efficient equipment to recycling nearly everything […]

Where Manufacturing AI Fits (and Where It Doesn’t) in Our Precision Machine Shop

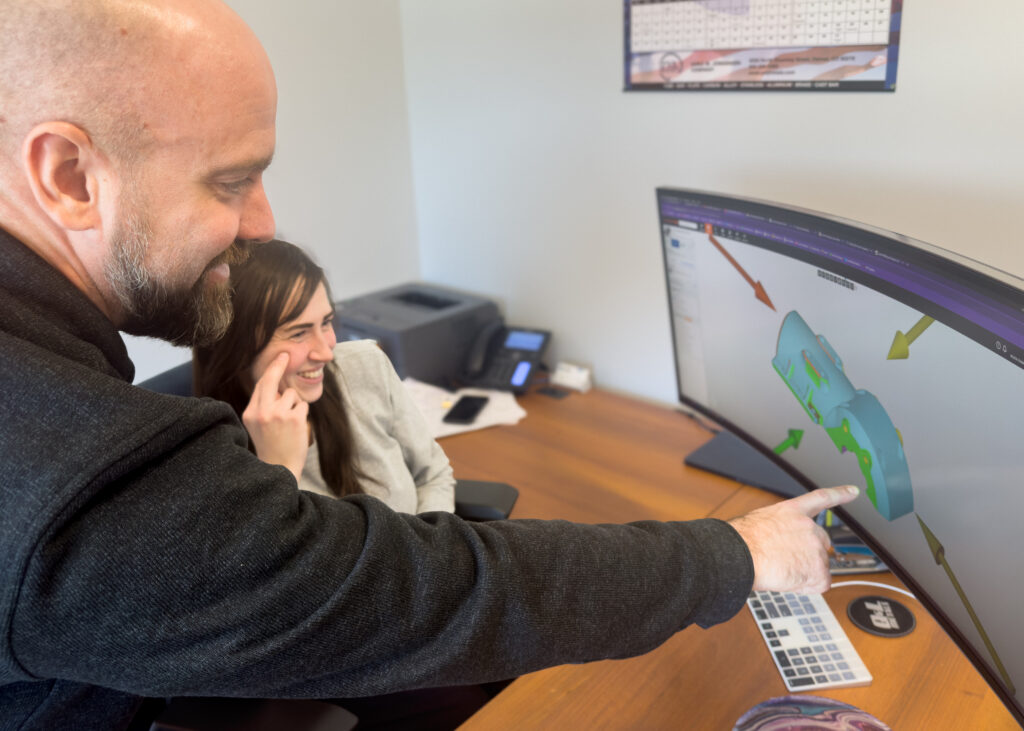

Artificial intelligence (AI) is transforming every industry, and manufacturing is no exception. At Reata Engineering, we’ve seen firsthand how manufacturing AI can drive efficiency and insight; however, we have also identified where it doesn’t belong. As a Colorado machine shop built on human expertise, we’re embracing AI carefully, applying it where it adds real value […]

Inside the Mindset of Reata’s Leadership Team, Built on Accountability and Transparency

In a fast-paced Colorado machine shop like Reata, success depends on our people, both the skilled professionals on the shop floor and the strong leaders guiding them. Behind each precision component and every on-time delivery is a leadership team dedicated to alignment and continuous improvement. Our leadership philosophy is rooted in the Entrepreneurial Operating System […]

How Reata Selects the Right Plating Vendor for Your High-Precision Parts

Vendor qualification is something we take very seriously at Reata. Partnering with the right plating vendor makes all the difference when it comes to maintaining tight tolerances, achieving consistent finishes, and meeting customers’ production deadlines. The way we onboard and manage our plating partners ensures quality results and no surprises for our customers. Continue reading […]

The Cost of Redesign Is Time! Avoid Delays with Design for Manufacturing

Every decision matters in manufacturing, and this is especially the case during the part design phase. When companies skip design for manufacturing (DFM) early in the process, they could end up paying the steepest price of all: time lost. Working with a precision machine shop that emphasizes DFM ensures fewer redesigns, faster turnaround, parts that […]

Decoding the Cost of Machined Parts

When customers request quotes for machined parts, one of the first questions we hear is: How do my unique specifications influence cost? The truth is, pricing isn’t just about raw material and machining time; it’s about design choices, finishing requirements, and the complexity of the part itself. At Reata, we believe in transparency and in […]

How Manufacturing AI Is Helping Reata Preserve Culture, Consistency, and Customer Trust

With technology constantly evolving, companies have a choice: adapt or fall behind. Here at Reata, we prefer to take this one step further by leading the charge, investing in software and adopting cutting-edge tools that we believe will make a great impact on our industry. And with our latest innovation, manufacturing AI is at the […]

Quality Assurance Isn’t Just a Department; It’s Part of Our Culture!

At Reata Engineering, quality assurance isn’t limited to inspection at the end of production. It’s woven into every step of our operation. From quoting to shipping, quality is a mindset, a process, and a commitment shared across the entire company. We don’t view quality as a box to check, but rather as an opportunity to […]

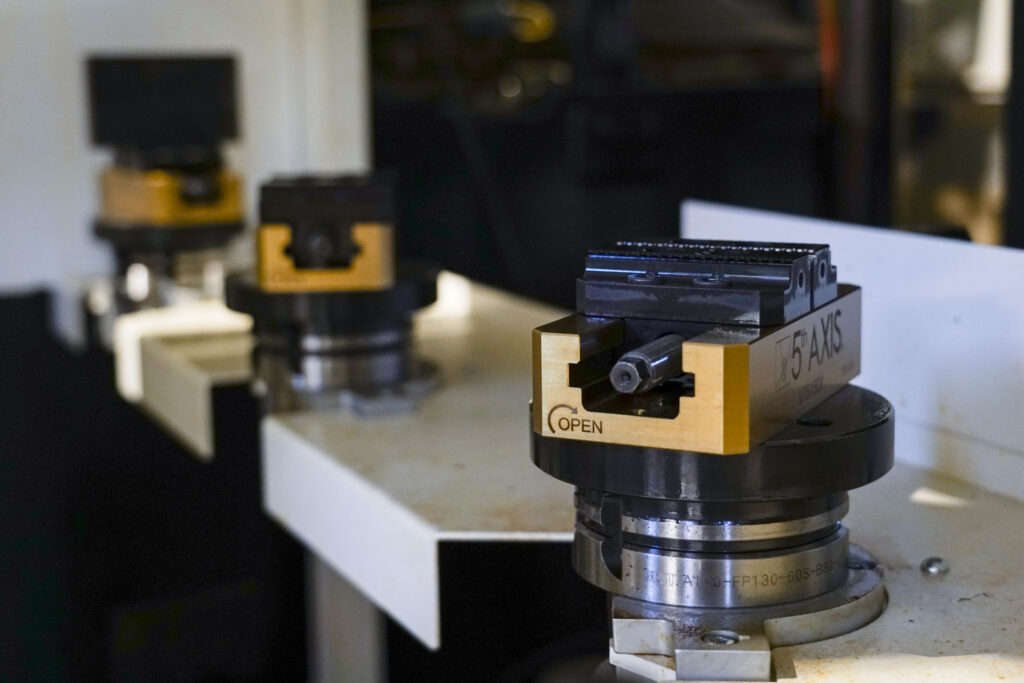

Why Automation Makes Sense for Low-Volume Production

When most people think of automation in manufacturing, they imagine high-volume automotive production lines with robots working 24/7, cranking out tens of thousands of identical parts. That image isn’t off-base; in fact, many U.S. automakers pioneered the use of automation and robotics on the shop floor. But today, automation isn’t just a means for mass […]

Prototype Machining Services That Don’t Disrupt Production

Prototype processes need to happen quickly, and so should prototype machining services. However, for many shops, prototyping can fall behind full-scale production in the ongoing list of priorities, especially if they lack the technology or processes to handle both simultaneously. At Reata Engineering, we’ve designed our shop floor to ensure prototyping and production can coexist. […]